Product

Counter

Online : 2

Today's view : 172

Yesterday view : 325

Visited : 350462

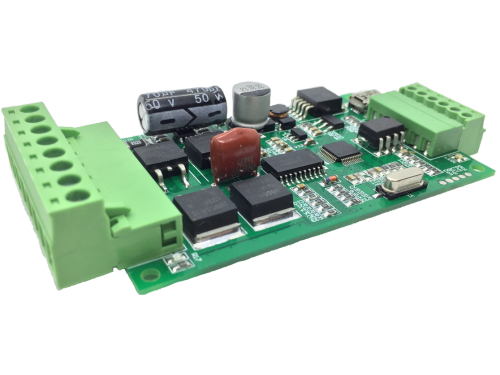

MSD_E3

Feature

- 6-30VDC, 0-3A, 1-30W.

- Position, Velocity, Acceleration Control.

- Autor Turning Tool Support.

- Follow Over Protect, Encoder, Motor Fail Protect.

- Over Current, Over Temperature, Short Circuit Protected.

- Support USB Communicate with DcTurningPro Sofware.

- Support Virtual Com Port to communicate with users.

- Communication: Pulse/Dir, UART, USB, Analog (Velocity Mode).

- Close Loop Support: Smart PID, PID, PI, State Feedback.

- H-Bridge mode with over current, temperature...protect.

Quantity

Introuduce:

- The motion is very important and popular today. They appear in all most areas.

- Special the motor, that is a big part of this fill.

- There are many Dc Servo Drivers in the market but they are very special (not open), more expensive, so big...

- Our driver is very small, low cost, more friendly, more open.

- The driver has an Autor Turning Tool which auto-detect motor information.

- There are many communication methods Pulse/Dir, Uart Network, Virtual Com Port, Usb.

- There is software that can configure, control, simulate, visual.

Application:

- Evaluation Close Loop, Research.

- Robot, CNC, Automatic.

Demo:

1. Licenses ID:

Using this key HDHGILBOHFIEGDGN for DcTunerPro Software

2. Setting processing: (6 steps to config the Driver)

- Connect motor -> Encoder -> power to driver (Make sure correct power supply direction).

- Setting Encoder -> Save* -> Reset* (*: No need when config by the button)

- Turning (The driver will identify the Motor properties in this step)

- Choosing Mode Control: Position or Velocity

- Choosing Method Control: Pulse/Dir, Uart,...

- Save -> Reset.

3. Connection:

4. Mechanical Specification (unit: mm)

.jpg)

5. Pulse/Dir Communication: (Your MCU will genegray Pulse/Dir signal to control the driver)

6. Serial/Uart Communication: (Sending commands via Uart)

Uart Command List: ( Control Methods: UART/USB-UART (Vituar Com))

N0 ? : Help

Nx $xxx= Parameter_Value : Parameter Setting Group;

$001=20; Address of the Driver is: 20

$002=200; Encoder Line (Encoder resolution per Round)

$003=400; The main Motor Saft will run 1/400 circle per One Pulse from External Pin (Pul/Dir).

$004=4; Model Close Loop Type (0: Turning, 1: None, 2: PID Position, 3: PI Velocity (recommend), 4: Smart Position (recommend), 5: None, 6: H-Bridge mode (Working as H-Bridge))

$005=0; Communicate Methode (0: PULSE/DIR, 1: UART Network, 2: None, 3: Analog (Just for velocity Mode))

$006=2000mA; Current Limit

$007=12; Follow Error (rad(PositionModel) or rad/s(VelocityModel)): The Maximum different betwean ExtimateValue vs RealValue is 12

$008=1; Motor Protection Active (0: Disable, 1: Enable)

$009=115200; Uart Baudrate

$010=2; Delta Position Expect When press the TEST Button (Circle)

$011=60; Velocity Expect When press the TEST Button (Round/s)

$012=500; Acceleration Expect When press the TEST Button (Round/s2)

$020=4870; Kp_P=4870

$021=0; Ki_P=0

$022=69; Kd_P=69

$023=33; Kp_V=33

$024=1144; Ki_V=1144

$025=0; Kd_V=0

$026=0; Kp_I=0

$027=0; Ki_I=0

$028=0; Kd_I=0

$101=0; MCU(0: Runing, 1: Saving & Reset; 2: Reset; 3: Factory Reset & Reset;)

Nx [p/P value] [v value] [a value] : Moving motor Nx with p/P,v,a parametter

Nx: x Adress Of Driver (0: Broadcast ; 1->99: Unicast)

p: Absolute Position Value (Option)

P: Relative Position Value (Option)

v: Velocity Value(Option)

a: Acceleration Value (Option)

Example: (The Driver 1 go to 100rad with Velocity 50rad/s and Acceleration 600rad/s2): N1 p100 v50 a600

Nx [d value] : d= Duty Cycle in H-Bridge Mode ($004 = 6); (Value Range: -900 to 900)

Note: "-": Direct =0 ; "1": Direct = 1 ;

Nx O [Kx] [T] [Mx] [Dx] [S] [L] [U] [r] [R101] [Gx] [C] ; (O: Operation Group Command)

[ ] : Option

Kx : Ack command respond (K1: Enable (default at start up MCU); K0: Disable

T: Turning The Motor

Mx: Control Method = M4 (M3: PI Velocity, M4: Smart Position, M5: None, M6: H-Bridge mode (Working as H-Bridge))

Dx: Communicate Methode = D0 (D0: PULSE/DIR, D1: UART Network, D2: None, D3: Analog (Just for velocity Mode))

S: Saving All Parameter

L: Loock/Pause/Stoop the Motor immediately

U: Unlook Motor

r: Reset the Current Position to 0

R101: Reset the driver

C: Clear error list

G: Get moving infor (G1: One Time; G3: Unitil Receive a New Data With Frequency Respond 5Hz; G255: One time with Randome Delay)

7. Error Codes:

E1: Follow error (so big difference between estimate position vs current position)

E2: A+ and B+ are wired in reverse. The user may solve this by swapping the A+ B+ connections or

motor’s wire connections.

E3: Faulty encoder. No signal from the encoder. The motor is stuck.

E4: Faulty motor wiring or just faulty motor in general.

E5: Over current detected.

E6: Voltage is out of range.

E7: Calibration fails. Unable to detect the properties of the motor.

E8: Temperature is too high.

8. Install Software & Driver: (using DcTunerPro to config the driver)

- Install the driver from ".INF" file :

- Fix issues "The third-party INF does not contain digital signature information":

- Install DcTunerPro.

US:

robotshop.com

Other Products

Working Voltage: 10-40VDC

Continuous Current: Up To 10A

Power Max: 200W

Quantity: 300

Working Voltage : 8-40VDC

Continuous Current: Up To 10A

Power Max: 200W

Quantity: 199

Working Voltage: 10-40VDC

Continuous Current: Up To 20A

Power Max: 600W

Quantity: 180

Working Voltage: 10-40VDC

Continuous Current: Up To 10A

Power Max: 280W

Quantity: 240

Working Voltage: 10-40VDC

Continuous Current: Up To 20A

Power Max: 600W

Quantity: 79

Operation Voltage: 10-30/40DCV

Max Continous Current: 20

Max Power: 400W

Quantity: 3